School of Engineering

Process Improvement Strategies

This project used the DMAIC methodology for continuous improvement of existing processes. The main objective was to achieve a win-win business strategy between Motorola and Jurong Hi-Tech (JHT) through Back End (BE) cycle time improvement without compromising the quality of the assigned 47N07 and 47N05/N06 modules. Furthermore, this project aimed to establish a lean transformation program to JHT (Malaysia) modules operation.

Key Features

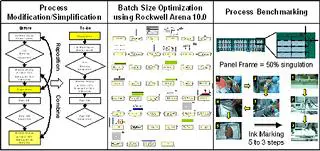

- Process modification/simplification

- Batch size optimisation

- Process benchmarking

- Reduced BE cycle time by 16.2% & 33.3% respectively

- Improved 47N05/N06 ink mark quality in terms of rework percentage from 10% to 0.1%

- Generated additional revenue of >S$1M per year for the company

- Reduced headcount and achieved cost saving of S$24K per year